Filum vectis omnibus connectoris cellulae solaris taeniae

Descriptio

Proprietates Mechanicae Fili Solaris Tabbing:

1. Elongatio: E-Mollis >=20% U-Mollis >=15%

2. Robur tensile: >=170MPa

3. Inclinatio lateralis: L<=7mm/1000mm

4. Punctum liquefactionis stannii ad soldandum: 180~230°C

Resistivitas Electrica Cupri:

TU1<=0.0618 Ω·mm2/m; T2<=0.01724 Ω·mm2/m

Cuprum Nuclei TU1 Off-Cu vel ETP1:

1. Puritas Cupri >=99.97%, Oxygenium <=10ppm

2. Resistentia: ρ20<=0.017241 Ω·mm2/m

Resistivitas electrica taeniae:

(2.1~2.5) × 10⁻² Ω·mm²/m

Crassitudo laminata:

1) Ferulatio manualis: 0.02-0.03mm per latus

2) Machina-Soldatio: 0.01-0.02mm per latus

Compositio Materiae Inductae:

1) Producta seriei plumbeae:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Series productorum sine plumbo:

A. Sn 96.5%, Ag 3.5% (Bi)

B. Sn 97%, Ag 3% et cetera.

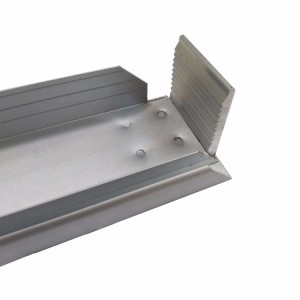

De Taenia Tabbing et Taenia Bus Bar

Taenia photovoltaica ex cupro et mixturis obductis constat, et in taenias tabulares et taenias vectis omnibus dividitur.

1. Taenia Adhaerenda

Taenia tabularis vulgo latera positiva et negativa cellularum in serie coniungit.

2. Taenia vectis omnibus

Taenia vectis omnibus fila cellularum in capsam iunctionis concentrat et currentem electricum dirigit.

De Obductione Mixturae:

Genus obductionis a consilio et postulatione emptoris determinatur. Dividitur in obductiones plumbatas et sine plumbo. In praesenti genus obductionis plumbatae late adhibetur, sed in futuro ad genus obductionis sine plumbo evolvetur.

specificationes

| MAGNITUDO (mm) | CRASSITAS (mm) | MATERIA CUPRAE | TOLERANTIA | ||

| WXT | Cuprum Basale | Toga per latus | Latitudo | Crassitudo | |

| 0.6x0.12 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 0.8x0.08 | 0.0500 | 0.0150 | TU1 | ||

| 0.8 x 0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.0x0.08 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 1.0x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.5 x 0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.5 x 0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.6 x 0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.6 x 0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.6 x 0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.8 x 0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.8 x 0.16 | 0.1100 | 0.0250 | TU1 | ||

| 1.8 x 0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.8 x 0.20 | 0.1500 | 0.0250 | TU1 | ||

| 2.0x0.13 | 0.0800 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 2.0 x 0.15 | 0.1000 | 0.0250 | TU1 | ||

| 2.0x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 2.0x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 2.0x0.20 | 0.1500 | 0.0250 | TU1 | ||

Processus Technologicus

1, Formatio filorum rotundorum in fila plana per tractionem et volutationem

2, Tractatio caloris

3, Stannatio per immersionem calidam

4, accurata convolutio

Basis cuprea est laminae cupreae sine oxygenio, per machinas volubiles ultra-precisas e Germania importatas, pertractatae.

Est elegans et sine margine laminari, mollis durities secundum desiderium emptoris aptari potest.

Formula peculiari adhibita, stratum e mixtura stanni per apparatum professionalem ad immersionem calidam stanni faciendam ex Iaponia importatum producitur. Superficies strati est nitida et aequabilis, et habet efficaciam stabilem et validum antioxidantem, quod adiuvat ad augendam efficaciam sudurae. Crassitudo eius secundum desiderium emptoris aptari potest.

Taenia secundum modulum solarem eiusque dimensionem ad ordinem fieri potest.

Exhibitio Producti